Lotting Inventory: What It Is, When to Use It, and How It Affects Warehouse Operations

Lotting inventory, also referred to as lot control or batch tracking, is a method of managing inventory by grouping items with shared characteristics into identifiable "lots" or "batches." Each lot is assigned a unique lot number and often includes metadata such as manufacturing date, expiration date, and supplier details.

This article explores when lotting should be used, what it's used for, the impact on warehouse operations and additional insights for businesses considering or managing lotted inventory.

What Is Lotting Inventory?

Lotting inventory involves assigning a unique identifier (a lot number) to a group of inventory items that are produced or received at the same time and under similar conditions. This identifier travels with the product throughout its lifecycle… from receipt and storage to picking and shipping.

Each lot number can be used to trace the origin, production conditions, location and destination of the items, making it a critical component in industries where traceability and compliance are essential.

When Should You Lot Inventory?

Lotting inventory is not necessary for all products, but it becomes essential under specific conditions:

1. Regulatory Requirements

Many industries are legally required to track inventory by lot number to comply with safety, quality, or traceability regulations:

Food and beverage (FDA, CFIA)

Pharmaceuticals (GMP compliance)

Cosmetics

Medical devices

Chemical products

2. Perishable or Time-Sensitive Items

Items with expiration dates or best-before dates require lotting to ensure first-expired, first-out (FEFO) inventory management.

3. Recall Management

Lotting enables fast and accurate product recalls. You can trace defective items to their lot and notify affected customers, minimizing business disruption and legal exposure.

4. Supplier or Manufacturing Variability

When the quality of raw materials or production batches may vary, lotting helps isolate issues, track performance, or support vendor/supplier accountability.

5. Quality Control and Testing

Products undergoing batch-specific testing (e.g., chemical composition, strength, stability or contamination risk) require lots to tie results to a specific group of items.

What Is Lotting Used For?

Lotting serves multiple operational and strategic purposes, including:

Key Differences in Warehouse Actions for Lotted Inventory

Lotting introduces operational complexity into warehouse workflows. Here’s how it differs from managing non-lotted inventory:

1. Receiving

Lot numbers must be recorded at the point of receipt.

Most WMS systems allow manual entry, barcode scanning, or system-generated lot numbers. It is best to avoid manual entry since that increases the chances of human error and incorrect data.

Lot information (e.g., supplier lot, production date, expiration) is stored alongside inventory.

2. Storage

Items are often segregated by lot number in the warehouse.

Pallet labels or shelf tags reflect the lot ID to prevent mix-ups.

You may need dedicated or dynamic locations based on inventory turnover or product sensitivity.

3. Picking

Lot numbers influence picking strategy:

FEFO: Pick items that expire first, regardless of arrival date.

FIFO: Pick oldest received lot first.

Customer-Specified Lots: Some customers require or reject specific lots.

Warehouse staff must confirm or scan lot numbers during picking.

4. Shipping

Lot details are often included in packing slips or customer documentation.

Some industries require serialized lot records for each shipment.

5. Cycle Counting and Auditing

Inventory counts for lotted items must validate both quantity and lot accuracy.

Physical labels must match system data precisely, increasing the time and precision required during audits.

Advantages and Disadvantages of Lotting

✔️ Advantages

Enhances traceability and recall readiness.

Supports regulatory compliance.

Improves quality control and issue diagnosis.

Enables vendor performance tracking.

❌ Disadvantages

Adds complexity to warehouse operations.

Increases training requirements for staff.

Requires system support (e.g., ERP or WMS with lot control).

Errors in lot tracking can lead to incorrect shipments or compliance violations.

Best Practices for Managing Lotted Inventory

Implement a Lot Control Policy

Clearly define which items require lot control and under what circumstances.

Establish how lot numbers will be recorded. Will they be provided by the vendor or generated within the ERP/WMS system?

Use a Capable WMS or ERP System

Manual systems are prone to error.

Ensure the system can enforce lot controls at receiving, picking, and shipping stages.

Train Warehouse Staff Thoroughly

Staff must understand how to identify, verify, and handle lot numbers properly.

Communicate to staff what the impact of incorrect lot numbers will be on the organization. Otherwise, warehouse staff may view lot number recording as unnecessary extra work.

Standardize Lot Number Format

Use consistent formats (e.g., YYYYMMDD-BATCH) to reduce confusion and aid automation.

Communicate these standards to vendors so they can align to them. Note: Vendors may have their own internal standards, so ensure your system can accept a variety of formats. Most systems are flexible and accept any form of text as a lot number.

Validate at Every Step

Scanning technology or manual checks should confirm correct lot numbers at each transaction point.

Use Labels and Signage

Clearly label pallets, bins, or totes with lot information to avoid cross-contamination. Lotted inventory requires more label information than unlotted inventory.

Audit Regularly

Conduct cycle counts and internal audits to ensure lot data matches physical reality.

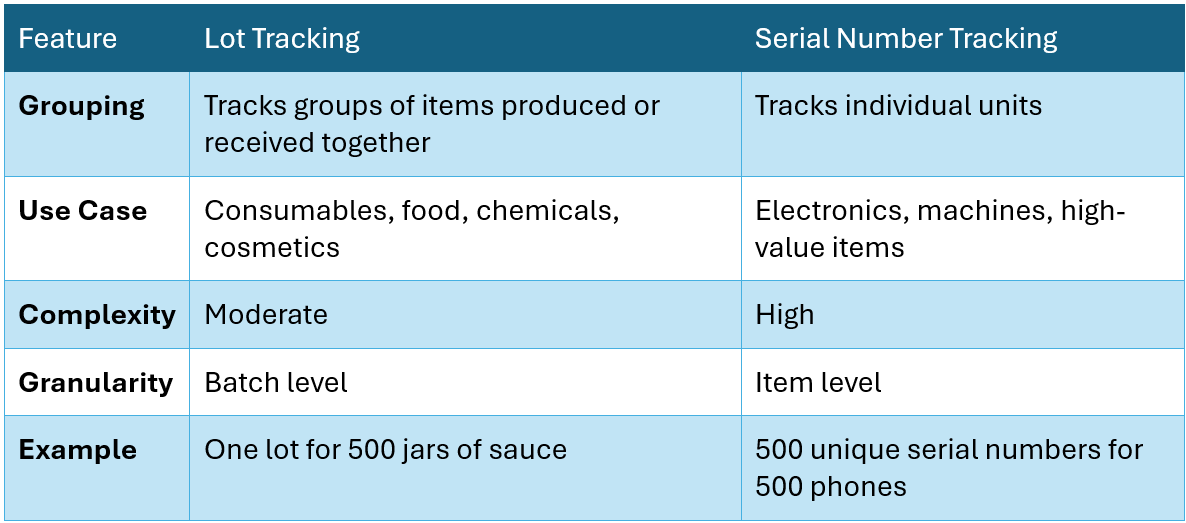

Lotting vs. Serial Number Tracking

Many ERP/WMS systems allow tracking of both lotted inventory and serialized inventory. Below is an explanation of the difference between the two tracking systems.

Conclusion

Lotting inventory is an essential strategy for businesses that require traceability, quality assurance, and regulatory compliance. While it adds operational complexity, the benefits far outweigh the risks… especially in industries where safety and consistency are critical.

Implementing lot tracking correctly ensures compliance, builds customer trust, improves inventory visibility and reduces the impact of recalls or quality issues.