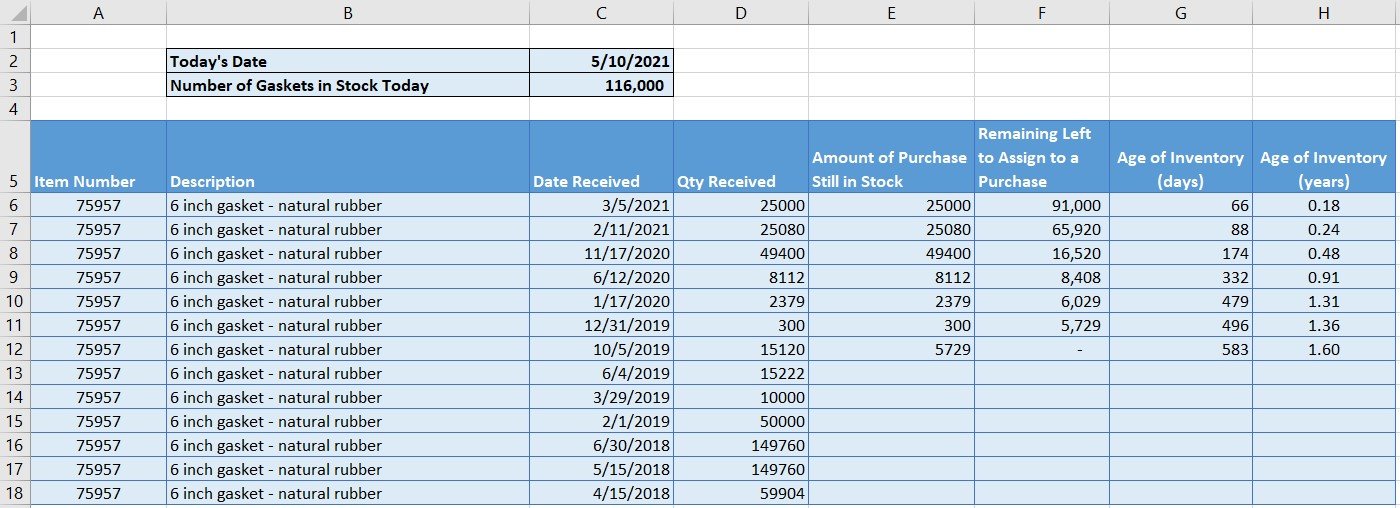

Discussion of inventory calculations and what to consider when choosing the values that go into your formulas.

We help business owners and leaders save money and increase profitability with our expertise in the following areas. Scroll down to read more about each topic.

Inventory analysis (dead inventory, inventory usage rates, product profitability),

Spend analysis (supplier consolidation for cost savings, RFPs),

Supplier performance analysis (delivery performance variation and adherence to contract terms).

The Benefits of Spend Analytics and Reducing the Supply Base

The Institute for Supply Management (ISM) reports that vendor spend analysis (supplier spend analytics) and supply base rationalization weigh heavily on the minds of executives and its significance is frequently underestimated. A 2013 Bain report found that companies using analytical techniques are:

Twice as likely to be in the top quartile of financial performance, and

Five times as likely to make decisions faster than their peers.

The goals of supply chain and procurement analytics projects are to identify savings opportunities with vendors, reduce excessive product offerings, reduce inventory, reduce the risk of obsolete or excess inventory, identify ways to reduce the number of suppliers, identify maverick spend and reduce the administrative burden of supplier/vendor management.

Intelligent use of data is now a competitive advantage and those that aren’t equipped to analyze their data yet may be leaving money on the table.

Definitions

-

Vendor Spend analysis is defined as the process of identifying current spend data to determine what is being spent, with whom, and for what.

-

Supply base rationalization is defined as a conscientious effort to determine the right number of suppliers to do business with. Reducing the supply base by using fewer suppliers can increase spend with each supplier and provide negotiation leverage with vendors. It also reduces the administrative workload that comes with managing a larger number of suppliers.

-

Product rationalization is the effort to reduce the number of products being offered by a company which can, in turn, reduce inventory quantities and the supply base. Products are analyzed by profit contribution, life cycle and customer priority.

Spend Analytics drives cost savings and optimizes the supply base

Whether you're a procurement specialist, supply chain manager or category manager, you need quick access to your spend data in order to make wise decisions and identify cost saving opportunities. We have performed vendor spend analyses for divisions inside large Fortune 500 companies and medium-sized businesses or business units.

Analytics is a specialized skill that most procurement teams don’t possess. This is where Numerical Insights can help. We possess the skills to:

Consolidate multiple sources of data,

Categorize data according to your own taxonomy or the national standard,

Create custom vendor spend dashboards to allow you to identify savings opportunities and off-policy spend.

If you have a long history of entering data manually, we can work with you to cleanse the data in preparation for analysis.

Case Studies

-

A U.S. division of a global manufacturing company carried over 6,000 different parts in its inventory. Each of these parts was a component of an assembly that the company sold to the automotive and heavy equipment markets.

Numerical Insights gathered several years of historical data on the usage and costs of these parts and analyzed patterns of demand. The analysis showed that 30% of the parts were only used once or twice per year. Based on this analysis, decisions were made as to which of these 30% of parts would still be carried and which ones could be ordered on demand from suppliers. Decisions were based on factors such as the value of the parts (contribution to inventory values on financial statements) and supplier lead times.

-

A global transportation company with millions of dollars in contract spend sought additional costs savings as a corporate initiative. Numerical Insights gathered data for off-contact spend and information on existing contracts. An analysis identified two categories of purchases that were being purchased off-contract. Working with the client’s procurement team, policies were communicated to each functional area to redirect that spend to existing contracts.

Examples of Features and Deliverables of Our Projects:

Customized visibility of your spend by category, by supply chain manager and by supplier geography

Identification of supply base rationalization/reduction opportunities (reduces vendor management needs)

Identification of off contract / rogue spend and cost saving opportunities

Creation of contract management databases or organization of existing contracts

Supplier performance analysis (including supplier delivery variation assessment and contract compliance)

Inventory analysis to increase cash flow and profit

Opportunities with Supply Chain Analytics

Product inventory is money tied up sitting on the shelf that can't be used elsewhere in the business. One big challenge for supply chain professionals is in deciding how much inventory to carry, when to order more and how much. The optimum solution is one that minimizes the amount of money tied up in inventory while still being able to fill each customer order. This challenge is driven by the fact that customer ordering can vary greatly each month as can your supplier delivery times.

For this reason, inventory analysis is a valuable activity. Numerical Insights has a proven methodology to provide you with insights into your customer demand patterns and supplier delivery variations. This information, combined with a prioritization scheme for your product offerings can:

Provide recommendations on how much inventory to carry (reorder quantities)

Tell you which products are high volume and which products customers rarely order

Show you how volatile or stable the ordering of each product is over time

Contact Us today to discuss how we can help you drive savings to the bottom line and increase efficiencies in supply base management.

Here are a few of our supply chain analytics and procurement blog entries and magazine articles:

No Fancy Number-crunching Tools Required (Supply Management Magazine - ISM)

The Monthly Metric: Demand Variability (Interviewed by the Institute for Supply Management)

The Monthly Metric: Percent of Rogue Spend (Interviewed by the Institute for Supply Management)

The Monthly Metric: Gross Margin Return on Investment (Interviewed by the Institute for Supply Management)

The Monthly Metric: Time-to-Ship (Interviewed by the Institute for Supply Management)